FLEX/G

Manage Your Internal Processes with Dynamic Scheduling

Make your operations more flexible and efficient with Flowmio’s Scheduling feature. FlowMio Scheduler aims to reduce costs and increase efficiency by enabling you to manage your production plans more effectively. At the same time, it improves the timing of your production lines, provides a seamless workflow, and allows you to use your work calendars more efficiently.

In the face of unexpected situations, priority changes, or newly added orders, you can perform all necessary calculations to adapt your production plan to changing conditions.

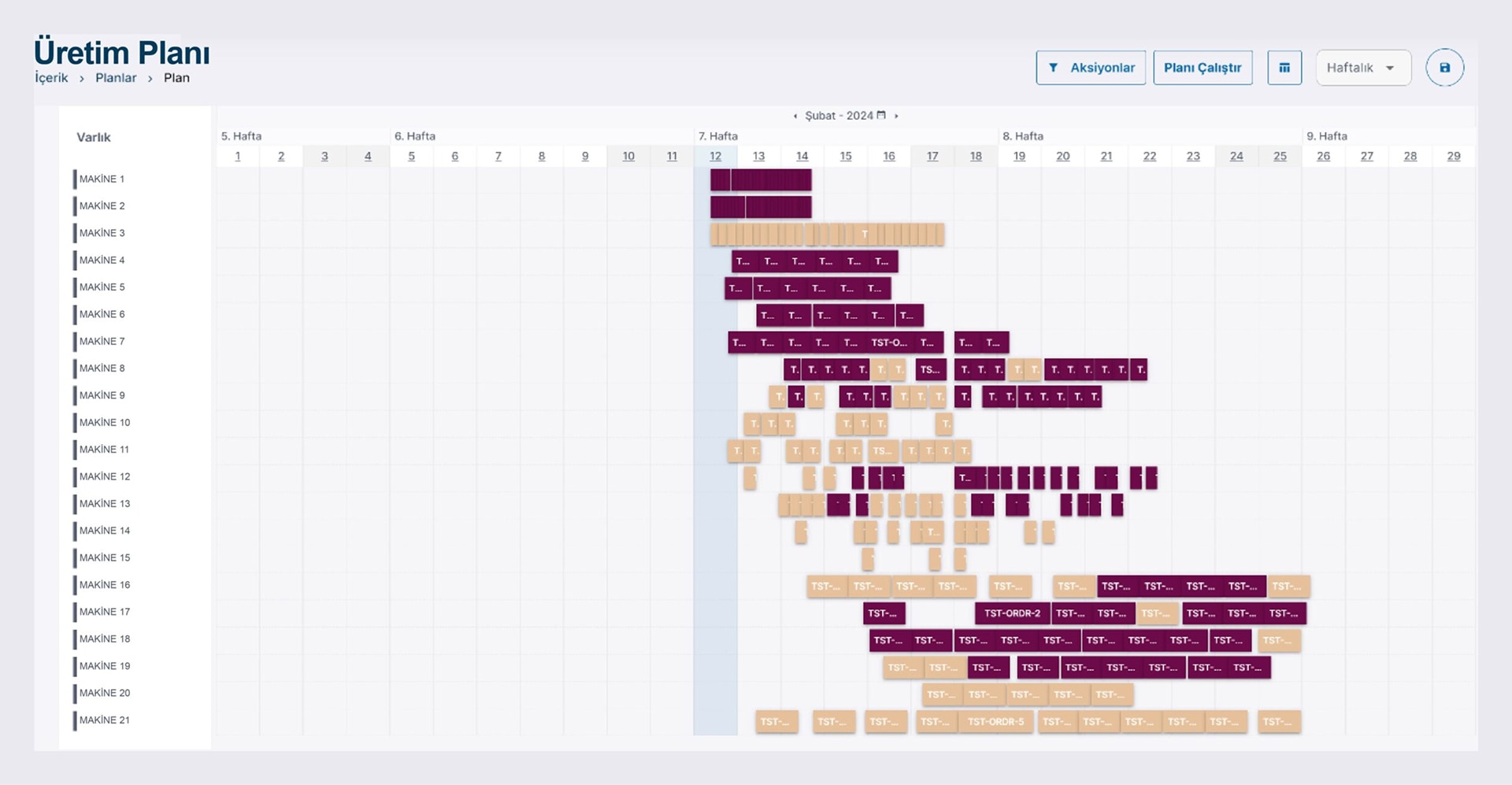

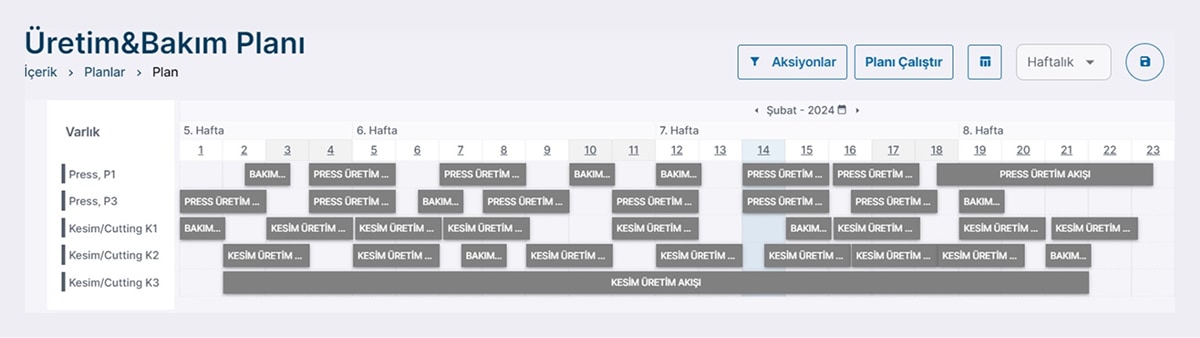

Gantt Chart View and Gantt Chart Editing

Station plans can be monitored and edited via the Gantt chart. Especially in complex production processes requiring the coordination of multiple tasks and teams, Gantt charts increase efficiency by organizing inter-task dependencies and timing.

At the same time, while optimizing resource allocation and prioritization, they help anticipate potential disruptions and conflicts, thereby increasing the flexibility of project plans and production.

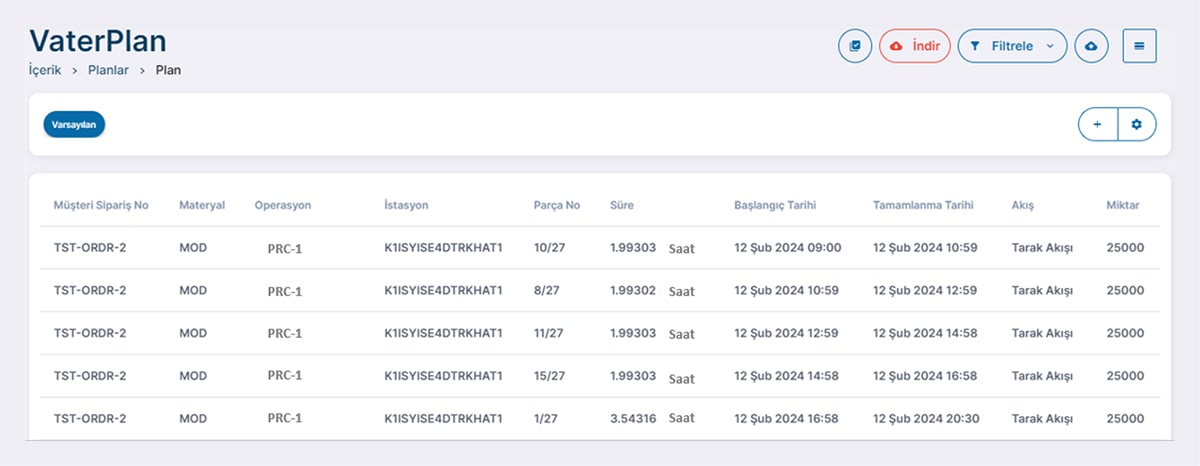

Exporting as Excel and Integration with ERP Systems

Transfer the data you need inwards or outwards while being able to integrate with ERP. Experience a seamless production-planning process. In table view, you can download the table view along with the fields you want and save it in Excel format. Similarly, if you have a plan table in Excel format, you can import it and deliver it to the field.

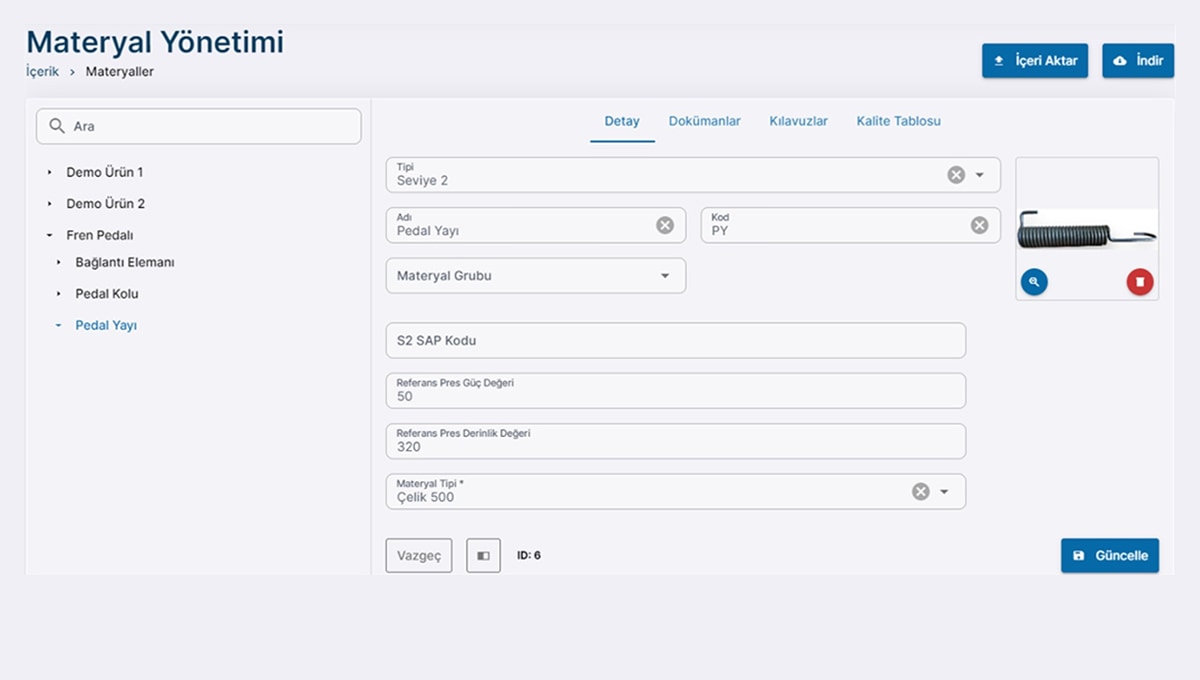

BOM | Bill Of Materials

Flexible Bill of Materials

You can create product trees (BOMs) on FlowMio or retrieve them from your ERP systems. By linking relevant documents, you can digitally facilitate communication between engineering and production.

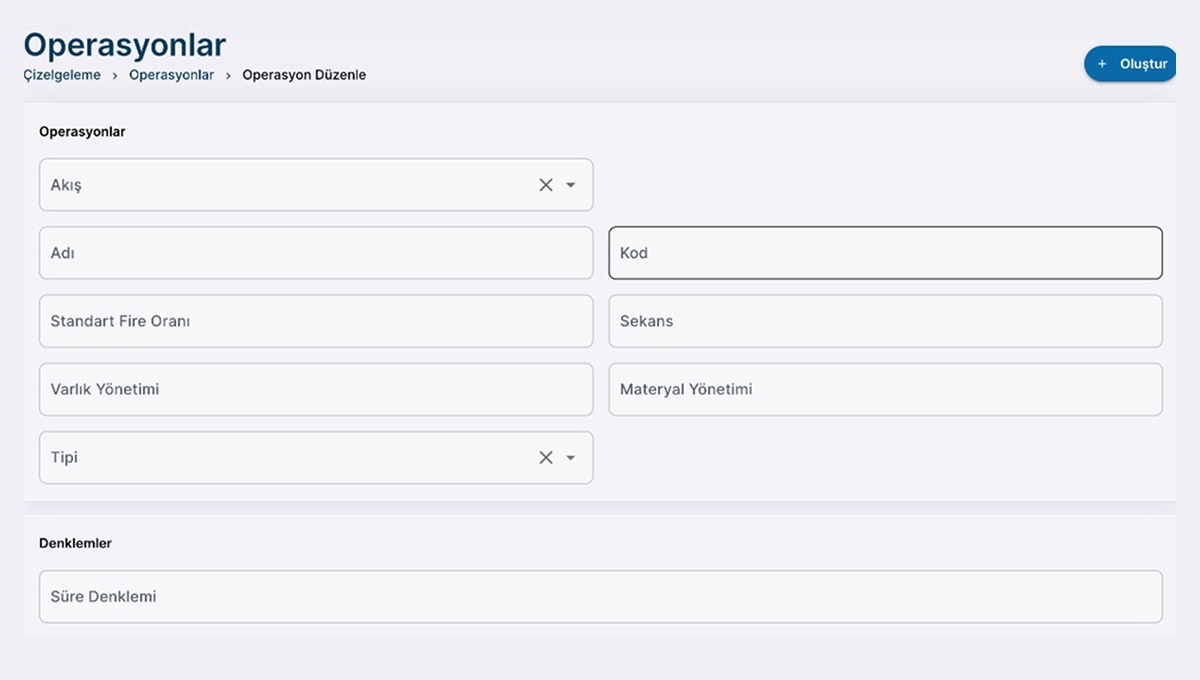

Bill Of Process

Flexible Route

Product routes are managed from the operations page; lines or machines can also be defined for a product or product group. Duration formulas can be defined with flexible equations prepared with institution-specific parameters.

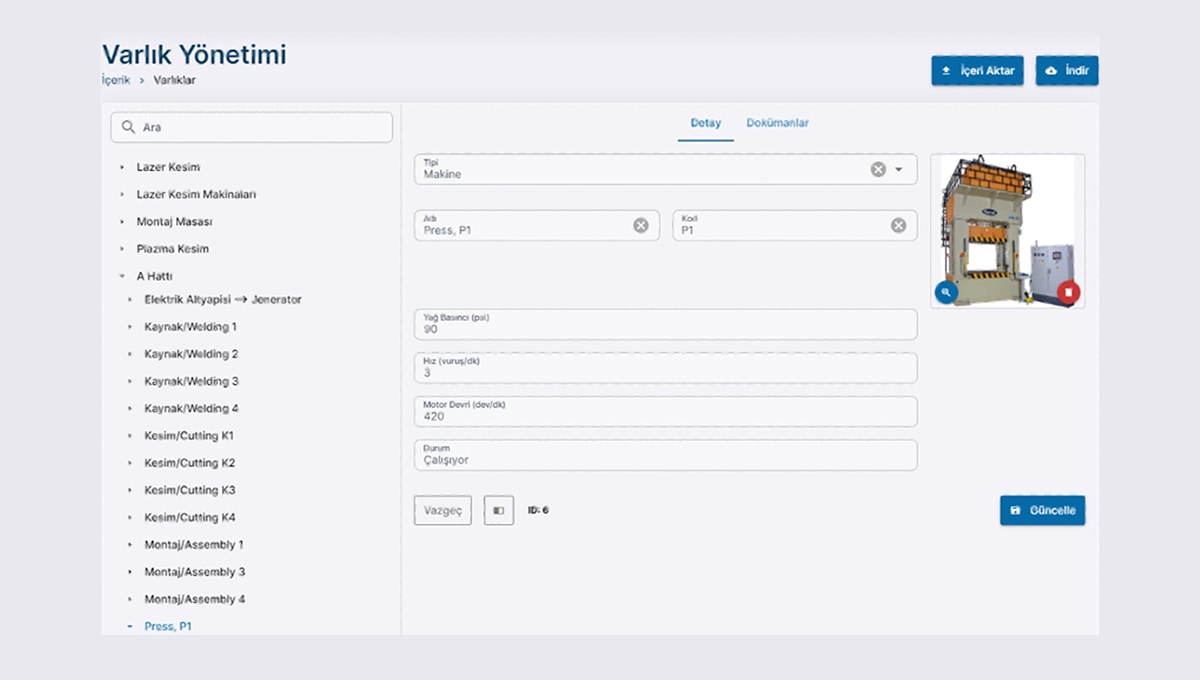

BOA | Bill Of Assets

Flexible Bill of Assets

Bütün varlıklarınızı tanımlayabilir üretim, bakım ve kalitenin aynı varlık yapısı üzerinden çalışmasını sağlayabilirsiniz.

Operator Panel Interfaces

Minimize Total Time

This objective function focuses on minimizing the weighted total completion time of the jobs. The weighted total completion time is obtained by multiplying the weight of each job by its completion time.

Minimize Total Tardiness

This objective function aims to minimize the sum of the tardiness durations of the jobs. It is based on the “Total Tardiness” criterion.

Minimize Weighted Total Time

This objective function focuses on minimizing the weighted total completion time of the jobs. The weighted total completion time is obtained by multiplying the weight of each job by its completion time.

Minimize Weighted Total Tardiness

This objective function aims to minimize the weighted total tardiness of the jobs. The weighted total tardiness is obtained by multiplying the weight of each job by its tardiness duration.

Minimize Weighted Total Flow Time

This objective function focuses on minimizing the weighted total flow time of the jobs.

Minimize Cost

This objective function aims to minimize a specific cost function when creating the schedule for the jobs. The cost function can be based on resource usage, processing times, and other factors.

Balancing

This objective function targets the balanced distribution of resources and jobs. It can ensure that resources are used equally or that jobs are distributed evenly.

FLEX modüllerini keşfedin

Discover FLEX modules

Üretim

Bakım

Kalite Kontrol

Planlama

Kurum İçi Süreçler

Ko-Pilot

Production

Maintenance

Manage operations smoothly by combining breakdown tracking and task planning.

Quality Control

Simplify quality processes with smart forms and automated checks.

Planning

Ensure tasks are completed on time by optimizing work schedules and management.

Internal Processes

Gain full visibility over operations with real-time dashboards.

Copilot

Accelerate decision-making processes with voice commands and AI insights.