Paperless Digital Factory. Within hours.

Modules

Collapse

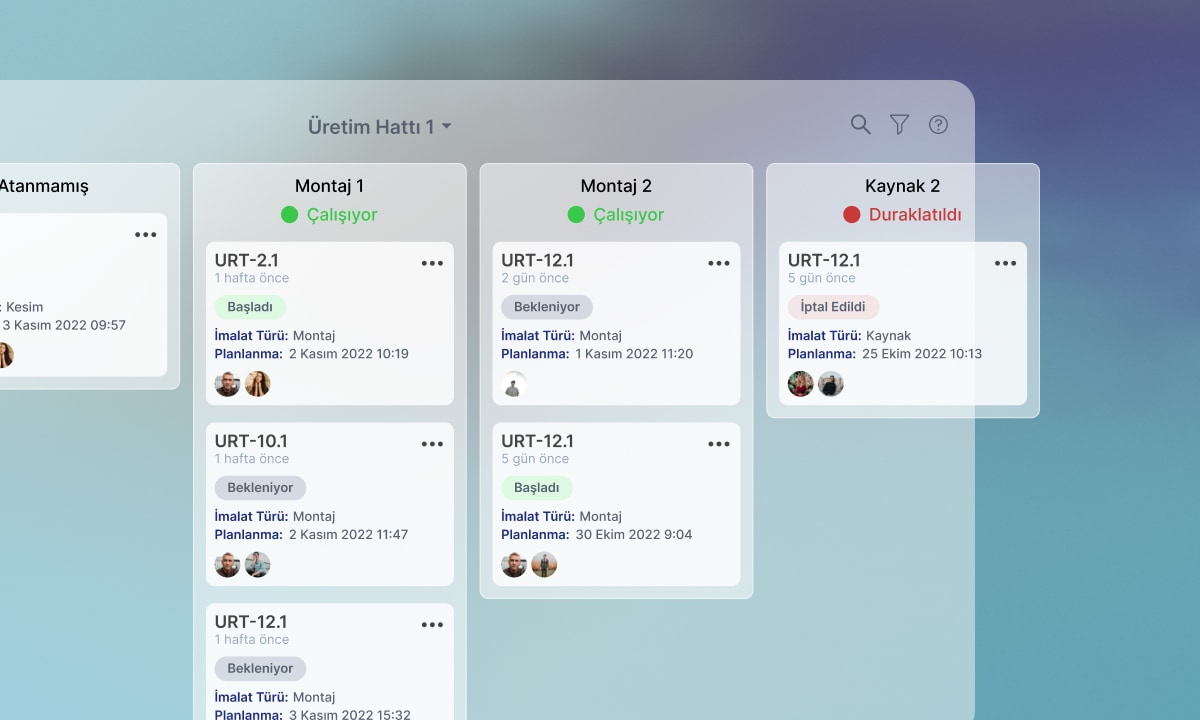

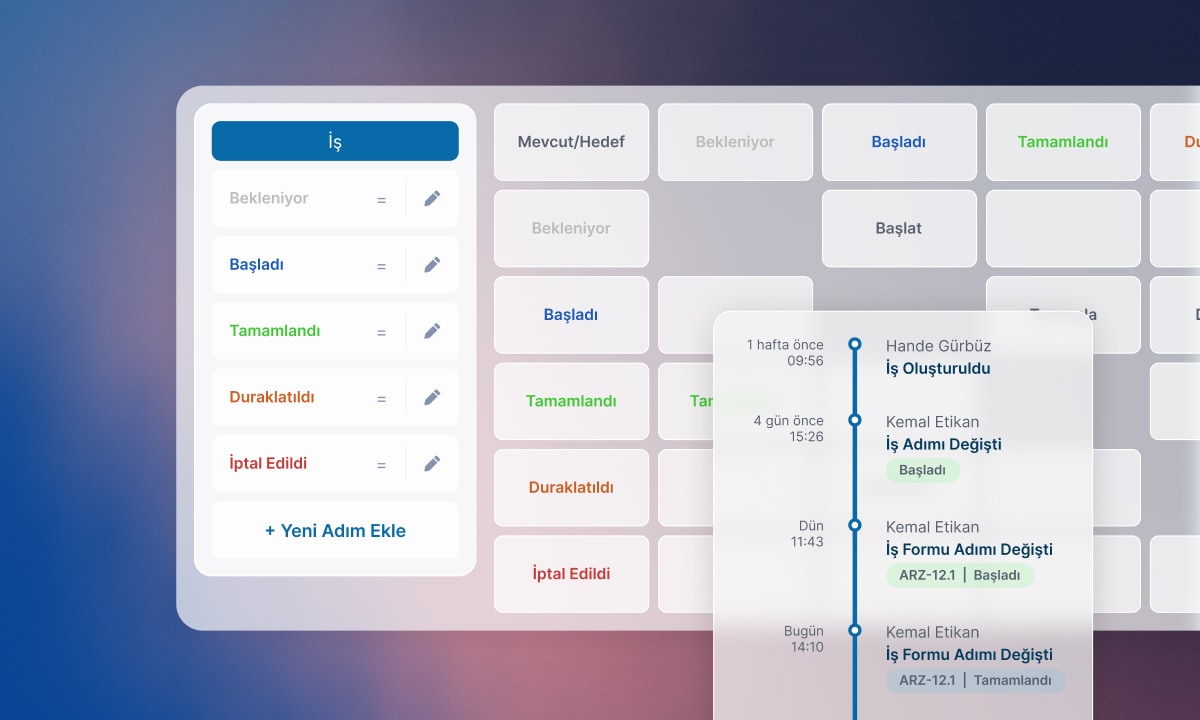

Production

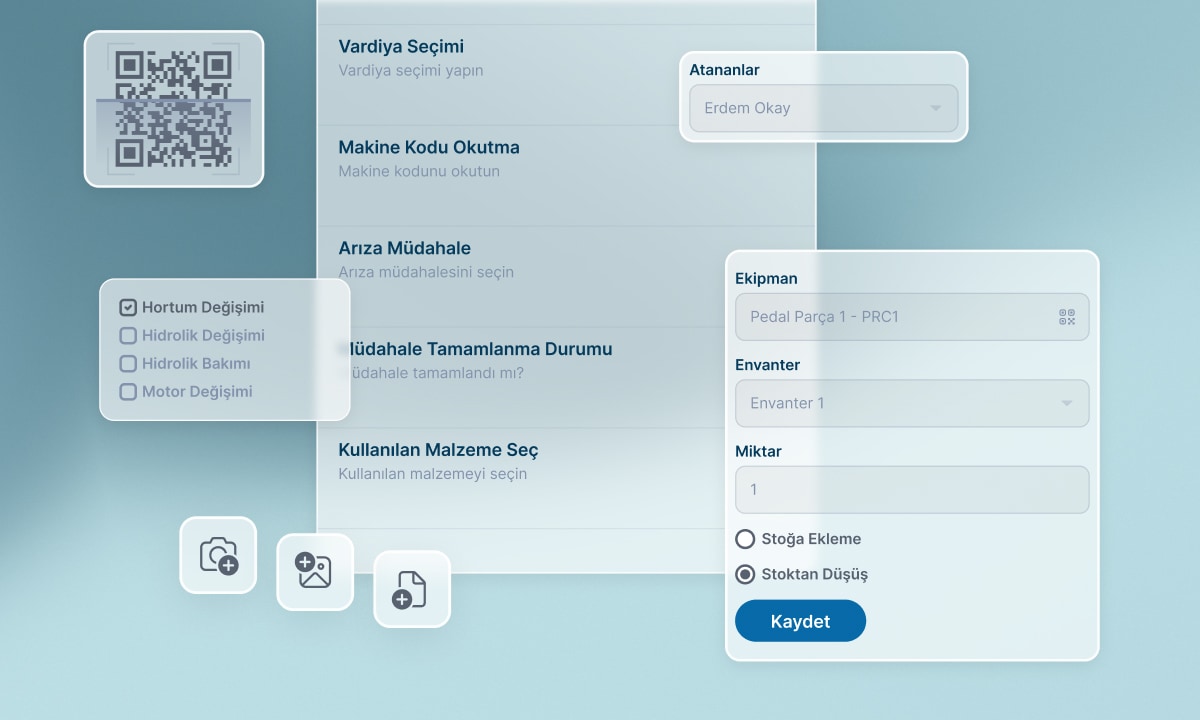

Maintenance

Quality Control

Planning

Internal Processes

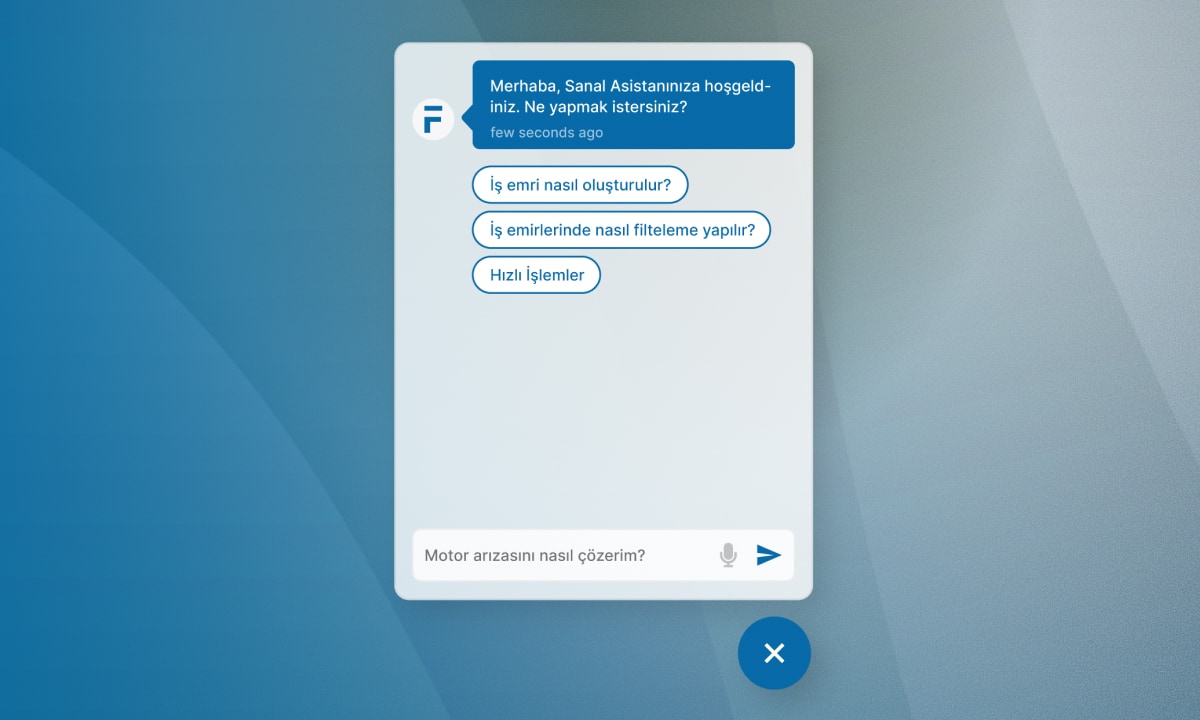

Co-Pilot

All in One Place: Integrated & Sync

Manage all your systems from a single point

Consolidate your entire digital infrastructure, from ERP systems to machines on production lines, quality measurement devices to image processing systems, onto a single platform. Synchronize your processes with real-time data flow, minimize errors, and increase your decision-making speed.

No code, no limit

Design your own digital factory with drag-and-drop

Digitize your processes without writing a single line of code. Create flows with a drag-and-drop interface, respond instantly to errors with alarm management and automation. Define, update, and manage processes according to your needs — fast and flexible.

Your Factory, At Your Fingertips

Instant field access with the mobile app

Manage production from the field with barcode scanning, image uploads, instant alarm notifications, and approval mechanisms. Track production from your mobile phone, speed up the process, make decisions without delay. Wherever you are, your factory is at your fingertips.

Smart Production with AI

Voice commands, smart analyses, digital assistant – all ready

Give voice commands to your factory assistant, make data-driven decisions with AI-powered reports. Make a difference in all processes from the production floor to management with fast analysis, suggestions, and automatic actions. Now your factory is not just digital, but also smart.

Adapts to Every Factory

Increase your profitability regardless of your production type and optimize your processes.

Automotive

Consumer Durables

Mining

Military & Defence

Food

Textile

Frequently Asked Questions

What functions does the FlowMio Production Management Platform offer?

What does a modular structure mean?

With FlowMio FLEX modules, you can start with the module that fits your current needs and gradually add new modules to your system as your requirements evolve.

Is the platform standard or customizable?

FlowMio is an industry- and company-independent platform that allows you to fully customize your processes thanks to its no-code infrastructure. Notifications, reports, and workflows can be configured without any additional development.

In which industries can FlowMio be used?

It is widely used in production-focused industries such as metal, automotive, defense, textile, food, casting, plastics, and chemicals. It is also preferred in industries like mining and energy, where process management and mobile monitoring are essential.

What do I need to get started?

Is technical knowledge required?

No. FlowMio can be easily used without technical knowledge thanks to its user-friendly interface. Our training materials and support team are with you throughout the process.

How long does the implementation process take and is it scalable?

You can integrate your workflows into the system within a few hours and start using it. FlowMio offers a scalable structure for businesses of different sizes.

How do you manage the digital transformation process?

We start by analyzing your processes and creating a roadmap at the beginning of the project. We proceed with an Agile methodology, implementing all steps transparently and quickly. We rapidly incorporate your feedback into the system.

What are FlowMio's standout differences?

FlowMio stands out with its no-code structure, AI-powered technology, real-time sensor integration, personalized digital Kanban boards, and dynamic graphics. It can be quickly adopted with its user-friendly interface without needing technical knowledge.

How long does the setup process take?

FlowMio is a cloud-based platform; setup time is a few hours. You can start using it immediately after defining your processes. We also offer on-premise installation support.

Can it be used in multiple locations?

Yes. FlowMio allows your teams in different locations to work synchronously. All data is stored centrally in the cloud.

Is the platform mobile-compatible?

FlowMio can be used via Android, iOS, and web browsers. Processes can be run instantly on mobile devices as soon as they are defined.

How can I use it from a mobile device?

You can manage all your processes on mobile by downloading the app to your iOS or Android device or by logging in via a web browser.

Does FlowMio offer a no-code infrastructure?

Yes. You can define, manage, and monitor your processes without any coding knowledge. You’ll feel like you’re developing your own application.

Is there AI support?

FlowMio Copilot offers an AI-powered assistant that operates via voice commands to manage production processes.

Is integration with existing systems possible?

It can integrate with many technologies such as ERP, PLC, sensors, image processing systems, and quality control devices. We offer tailored support for your integration needs.

Is OCR support offered?

Yes. Optical Character Recognition (OCR) automates manual data entry, increasing your processing speed.

Is my data secure?

FlowMio implements industry-standard data security protocols. All data is encrypted and accessible only by authorized users.

Are support and training resources available?

We are always with our users, providing 24/7 technical support, comprehensive training documents, and help content.

Can I request a product demo?

Certainly! To get to know FlowMio better, you can contact us or request a meeting directly from the calendar.

What is FlowMio's pricing model?

Pricing is customized based on the number of users and the modules you need. You can contact us for a personalized quote.

Üretiminizi Devrimsel Bir Şekilde Yenilemeye Hazır Mısınız?

Bir demo talep edin veya ücretsiz deneme sürenize bugün başlayın; optimize edilmiş süreçler, geliştirilmiş işbirliği ve eyleme dönüştürülebilir içgörülerle tanışın.